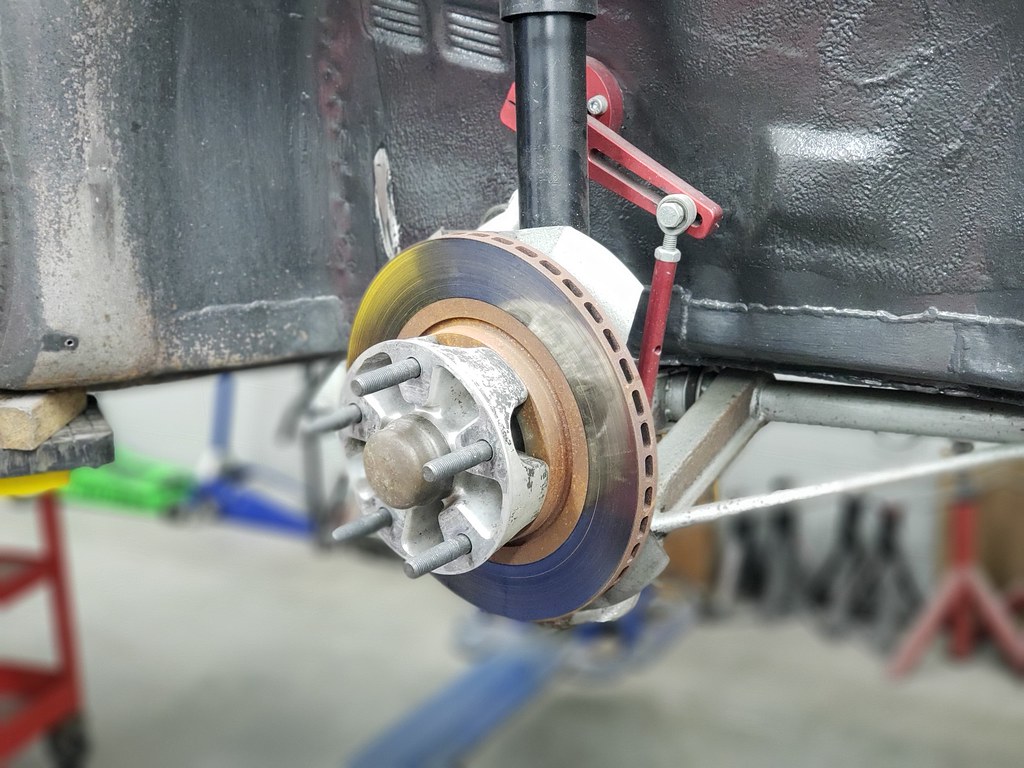

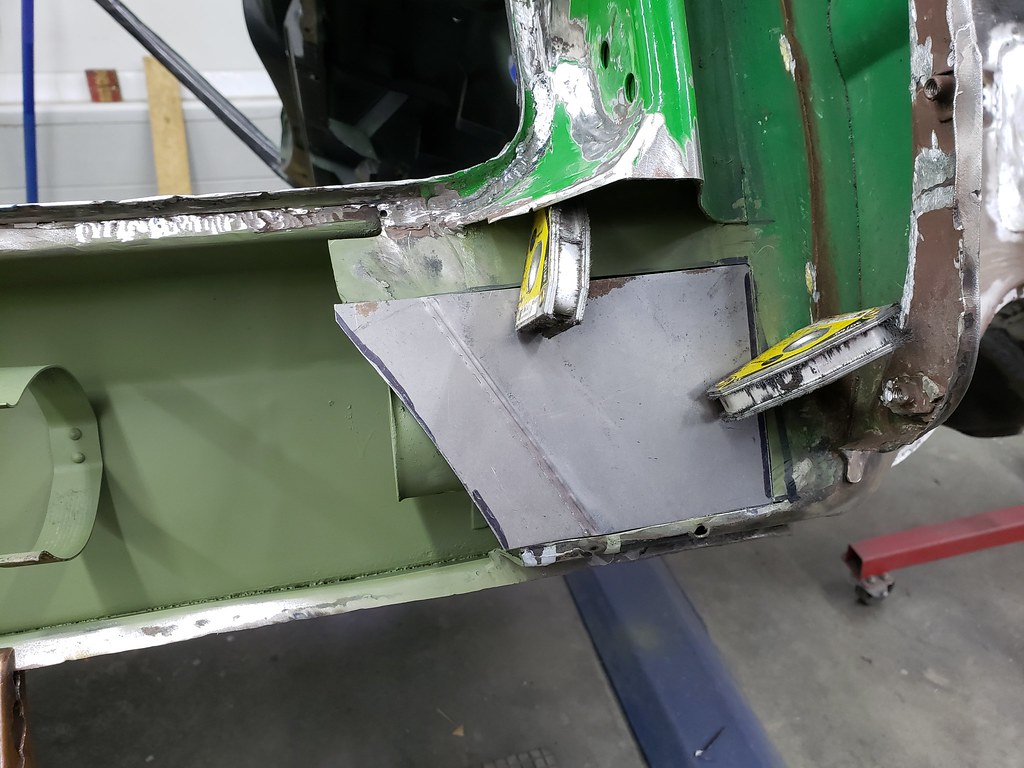

The 71 911 was my Autocross car for 10 years. But now it time resurrect it and built a nice outlaw 911. . Here are some pictures when I started disassembling the car

More to come.

Cheers

Engelbert

More to come.

Cheers

Engelbert

Comment